Centralized Lubrication Systems

Graco’s automatic lubrication systems provide a precisely measured amount of lubricant at frequent intervals to every lube point – even if they are hard to reach.

A typical centralised lubrication system consists of a pump, a control device and dispensers.

Control can be implemented using external controllers mounted, e.g. in the operator's cabin, or integrated with the pump, e.g. with the G3 pump.

GRACO dosing elements have a capacity from 0.01 cm3 to 19.7 cm3 for both greases and oils.

With GRACO central lubrication systems, we can be sure that each point has been lubricated with the right amount of lubricant and at the right time.

Please feel free to visit our online store:

Online Shop

-

MXP TRABON GRACO

GRACO MXP modular divider valves are reliable dosing valves for central lubrication systems. MXP valves are a guarantee of high quality in lubrication systems.Online Shop

-

MSP TRABON GRACO

The Trabon MSP Series is designed for quality, reliability, and ease of use for central lubrication systems. It was the original modular-style series progressive divider valve - and is still the best!GRACO MSP valves are a guarantee of high quality in lubrication systems.Online Shop

-

MHH TRABON GRACO

GRACO MHH modular divider valves are reliable dosing valves for central lubrication systems. MHH valves are a guarantee of high quality in lubrication systems.Online Shop

-

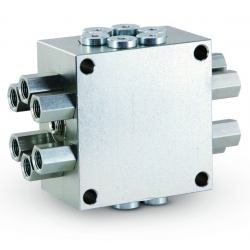

MSP-SS

GRACO MSP-SS modular divider valves are reliable dosing valves for central lubrication systems. MSP-SS valves are a guarantee of quality in lubrication systems.Online Shop

-

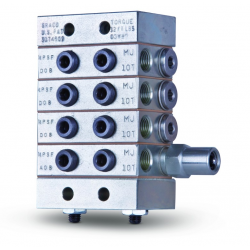

MJ TRABON GRACO

GRACO MJ divider valves are reliable dosing valves for central lubrication systems. MJ valves are a guarantee of high quality in lubrication systems.Online Shop

-

MX TRABON GRACO

GRACO MX divider valves are reliable dosing valves for central lubrication systems. MX valves are a guarantee of high quality in lubrication systems.Online Shop

-

AO MSP GRACO

Air-Oil LubricationGRACO AO MSP divider valves are reliable dosing valves for central lubrication systems. AO MSP valves are a guarantee of high quality in lubrication systems.Online Shop

-

MGO TRABON GRACO

The Trabon MGO Series offers the largest output available in a series progressive system. Ideal for heavy-duty and large bearing applications with wide temperature variations and high volume requirements.Online Shop

-

CSP GRACO

Compact Series Progressive (CSP) divider valvesGraco Quality in a Compact PackageCSP Valves - for the progressive delivery of mineral oil and grease for lubricationCombine with field-proven G-Series pumps for a complete system solutionOnline Shop

-

MD TRABON GRACO

The Trabon MD Series is the most compact series progressive solution making it a perfect fit for tight spaced applications.Features• Available with 2, 3, 4, or 6 outlets• Easy to install on new or existing equipment• Use our cycle indicator pin models to provide positive assurance of a successful lube eventOnline Shop

-

-

Air-Lube Spra-Control GRACO

Features• Conserves air - air required only during spray interval• Versatile - can be used with any centralized lube system or mechanical oiler and will handle grease or oil• External mix nozzle purges itself and prevents clogging• Saves lubricant - by spraying smaller amounts at frequent intervals, provides better film, no wasteOnline Shop

-

Thrif-T-Luber Graco

• Fast payback - easily pays for itself!• Easy system design and modification• Full range of metering amounts for lubricating almost any machine• Available in three types and ten flow ranges to meet lube requirements• Quality sintered bronze fi lters won’t shred or clog like felt filtersOnline Shop

-

Injecto-Flo® II

• Piston distributor style single line meters known world-wide for fast simple installation• Seven different groups with two different mounting types, thread to manifold or cast manifold to serve a broad range of lube point requirements• Metering nipples can be changed to fine-tune your dispense volumesOnline Shop

-

LubriSystem™ GRACO

• Convenient cycle indicator option allows for simple visual system troubleshooting• Two piece compression fitting included for fast, easy installation• Bundled system tubing for easy installation• Threaded outlet allows for manifold or direct-to-bearing mounting• Adjustable output volumeOnline Shop

-

GL-1™ GRACO

Rugged, medium-pressure metering system for pumping grease; ideal for heavier-dutyapplications such as cement batch plants or material processing equipment.Online Shop

AKTIM Sp. z o.o.

Braterska 12

30-802 Krakow

POLAND

KRS: 0000151916

VAT No: PL6790084772

DUNS: 422548743

BDO: 000027366

copyright all rights reserved 2019

tworzenie stron internetowych milleniumstudio.pl

aktim@aktim.com.pl

aktim@aktim.com.pl